Temperature Time Factor (TTF) calculations and compressive strength results are used for estimating concrete strength gain using the maturity method as outlined in ASTM C 1074. To develop the data used for this type of evaluation, cylinders are cast to be broken at certain intervals. The total curing time in either days or hours and the average curing temperature in Celsius are recorded when cylinders are broken. TTF is then calculated in accordance with the ASTM C 1074 test method. TTF numbers can either be calculated in degree hours or degree days depending on the time interval used. We calculate TTF in Degree hours to ensure compatibility with most of the hardware typically used in the field.

|

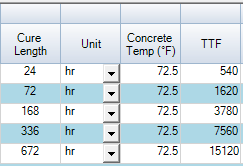

| Figure 1. |

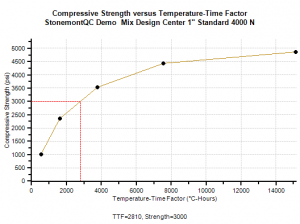

In Stonemont Software, TTF Values are either calculated or entered on the concrete cylinder entry form along with the corresponding compressive strength information as shown in Figure 1. Once this information is entered, it is automatically associated with the final mix design for analysis. Up to five of the most recent maturity tests are available for evaluations. Once a maturity test is selected the results are plotted on a graph as shown in Figure 2. For a given compressive strength value, a TTF value can be interpolated from the data. For a given TTF value, a compressive strength value can be interpolated from the data. There are several options for selecting the best-fit Line type used in the evaluation. The results of the evaluation can then be exported as an image file. In the example shown in Figure 2, 3000 psi was used to extrapolate the minimum estimated TTF value needed to reach that compressive strength. The best-fit line for the data used was point to point.

|

| Figure 2. |

Since maturity testing is managed with the mix design in our system, the user no longer needs to search for documentation elsewhere. Several evaluations can quickly be compared to determine if any changes have been made that affect the maturity results. No extra software is needed for data entry or evaluations leaving the user free to choose the hardware they want to use in the field for maturity monitoring. Managing maturity testing is a straight forward and intuitive process in Stonemont Software V7.

For more information please contact Stonemont Solutions, Inc.

Michael Rodriguez

Stonemont Solutions, Inc.