When to Use Aggregate Blending Constraints

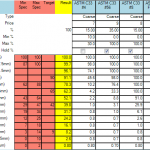

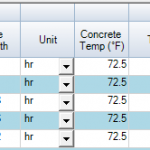

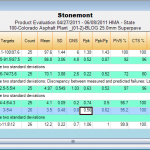

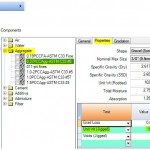

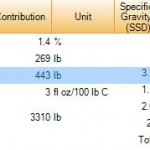

In a previous blog post on material blending we touched on some of the reasons why a user might want to employ material constraints while blending multiple aggregate products. I would like to expand on those reasons and add a few more to the list. The mathematical and visual blending tools available in StonemontQC for aggregate,