Using Fractions With Worksheets

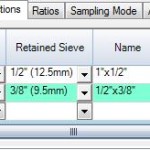

In StonemontQC, a fraction represents the material retained on multiple adjacent individual sieves. For example, material passing the 1” (25 mm) sieve and retained on the ½” (12.5 mm) sieve can be defined as a fraction (Figure 1). Note that in this example the ¾” sieve would have been included in the gradation test and