Pervious concrete mixes are paving mixes designed to have enough interconnected voids so that water can easily penetrate through the concrete and into the subgrade where it can be absorbed into the soil. Property that was once used for managing storm water runoff can potentially be reduced, leaving more useable land for other purposes. Rather than allowing runoff to discharge directly into streams or into a sewage treatment system; water is allowed to replenish the ground water system in a fashion similar to how the land absorbed water before it was developed. The subgrade thickness can be adjusted to hold varying amounts of water for absorption into the soil depending on the native soils ability to percolate.

Some areas like Florida see wide spread use of pervious pavements because they have significant storm water events and soils that allow water to percolate through them very easily. The use of pervious pavements is a desirable alternative to dealing with copious volumes of storm water runoff. Not all soils are suitable for the use of pervious pavements so the use of this product may vary from one area to the next. Void contents in pervious pavements may vary in design from 15 to 25 percent which may make them less suitable for heavy truck traffic. However; the use of aggregates specifically designed for pervious concrete and the use of admixtures to enhance the properties of the mix have greatly extended the suitability of this product for various applications. If designed, produced, placed, and maintained properly; pervious pavements can have a substantial service life. Many communities are now choosing pervious pavements as an integral part of their storm water management system.

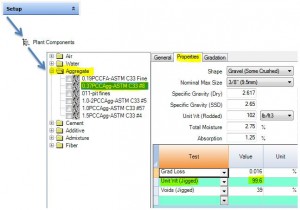

Creating a pervious mix design is now a straight forward process in Stonemont software. The main requirement is that the aggregate component must have a unit weight (jigged) quality test attached to it. This is necessary to calculate the amount of coarse aggregate in the mix. If project specifications or standard practice is to use alternative methods of consolidation such as a proctor hammer, just remember to save the results under the unit weight (jigged) quality test for the process to work properly.

Add the Air component to the component grid of the mix. Notice that it contributes to 100% of the mix because there are no other components in the mix yet.

Add the Air component to the component grid of the mix. Notice that it contributes to 100% of the mix because there are no other components in the mix yet.  Choose the Coarse aggregate to be used in the pervious mix and add it to the component grid. The mass and volume are calculated and subtracted from the air (void) content of the mix. At this point the percent of air should match the calculated void content of the Coarse aggregate.

Choose the Coarse aggregate to be used in the pervious mix and add it to the component grid. The mass and volume are calculated and subtracted from the air (void) content of the mix. At this point the percent of air should match the calculated void content of the Coarse aggregate.

Drop in the appropriate water component to the component grid. The air (void) content is reduced by the volume of water since it is partially filling the voids in the aggregate.

Drop in the appropriate water component to the component grid. The air (void) content is reduced by the volume of water since it is partially filling the voids in the aggregate.  Add a cement component to the component grid. The air (void) content is reduced by the volume of cement since it is partially filling the voids in the aggregate.

Add a cement component to the component grid. The air (void) content is reduced by the volume of cement since it is partially filling the voids in the aggregate.

If the mix is to include a supplementary cementitious material, add it now and adjust the percent of component accordingly. Notice how this effects the percentage of air (voids) in the mix.

If the mix is to include a supplementary cementitious material, add it now and adjust the percent of component accordingly. Notice how this effects the percentage of air (voids) in the mix. Continue to add any admixtures to the mix as needed for the mix design.

Continue to add any admixtures to the mix as needed for the mix design.

Components can be added to the mix in any order. I chose to enter them in this way to better illustrate the relationship of the components in a pervious mix. Creating a pervious mix is as straight forward as creating other concrete mix designs in concreteQC. The approach to pervious mix designs in StonemontQC allow the user to make changes to any of the components in the mix and quickly evaluate the effects those changes.

For more information on how easily you can create pervious concrete mix designs using concreteQC contact Stonemont Solutions, Inc.

Michael Rodriguez

Stonemont Solutions, Inc.